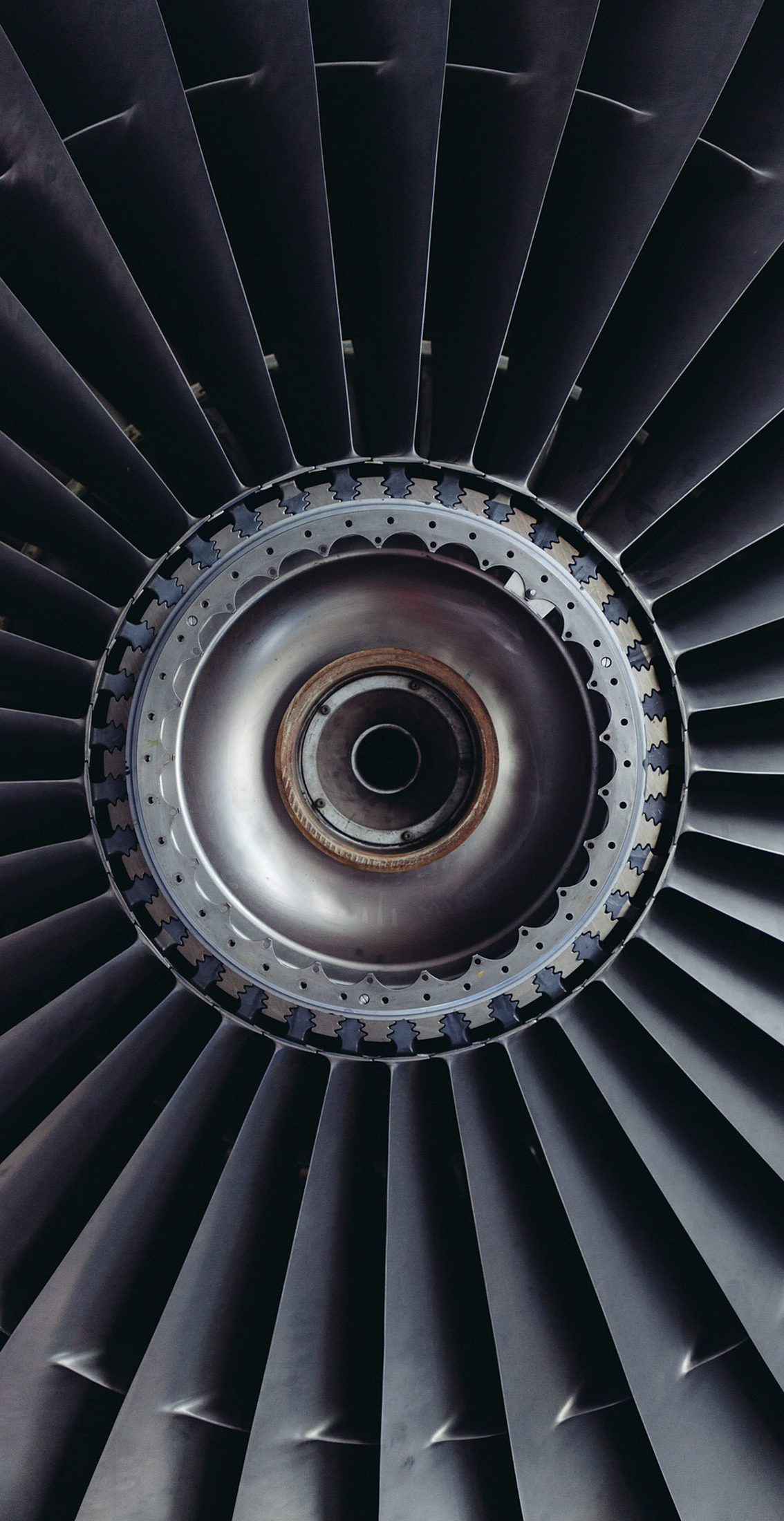

Heirs to over 70 years of know-how.

A key partner for major aerospace and defense contractors, the Bt2i group is structured around its centers of excellence, specialized in the production and assembly of complex mechanical and composite parts and sub-assemblies.

Backed by 70 years' experience, the group draws on the recognized expertise of over 1,000 employees.

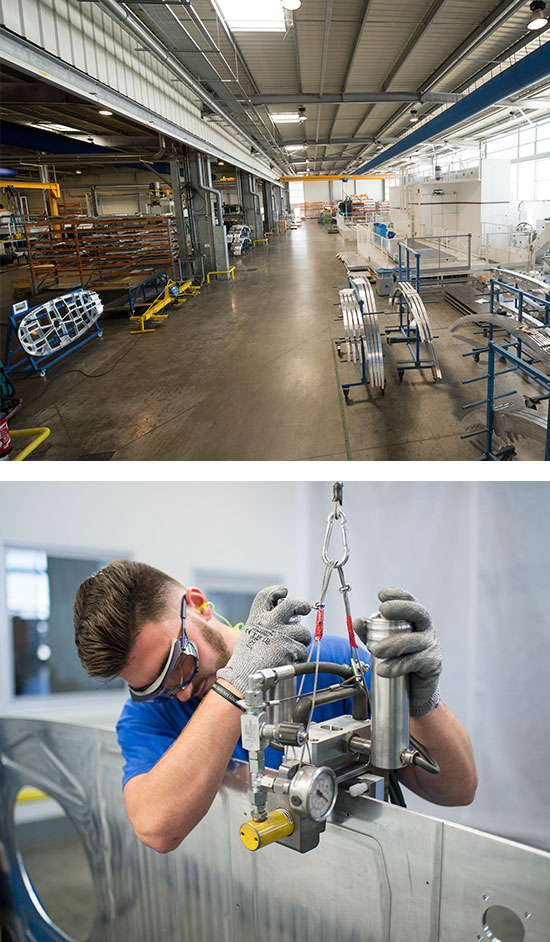

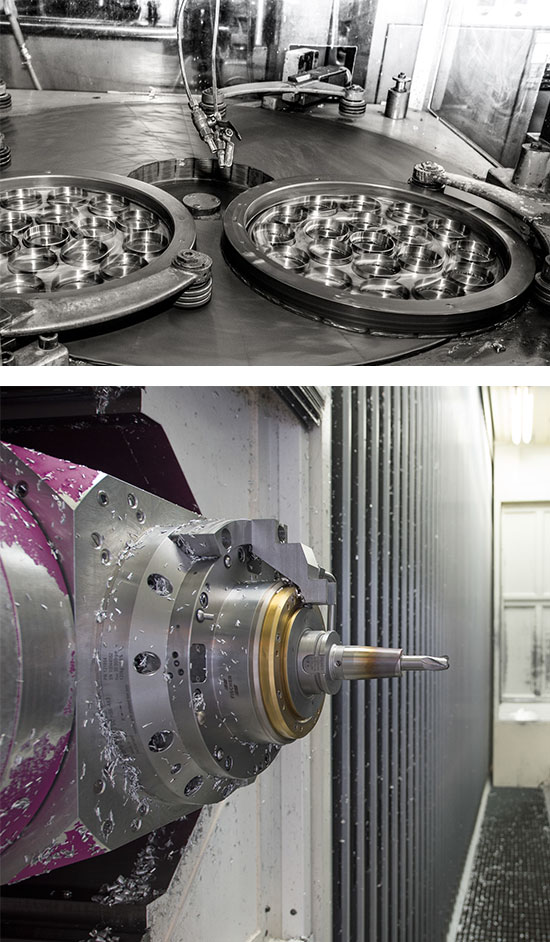

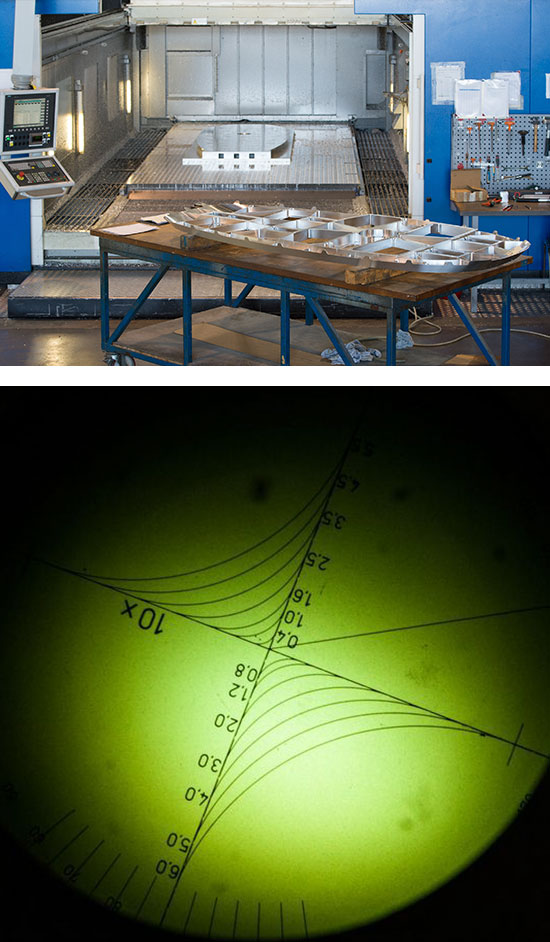

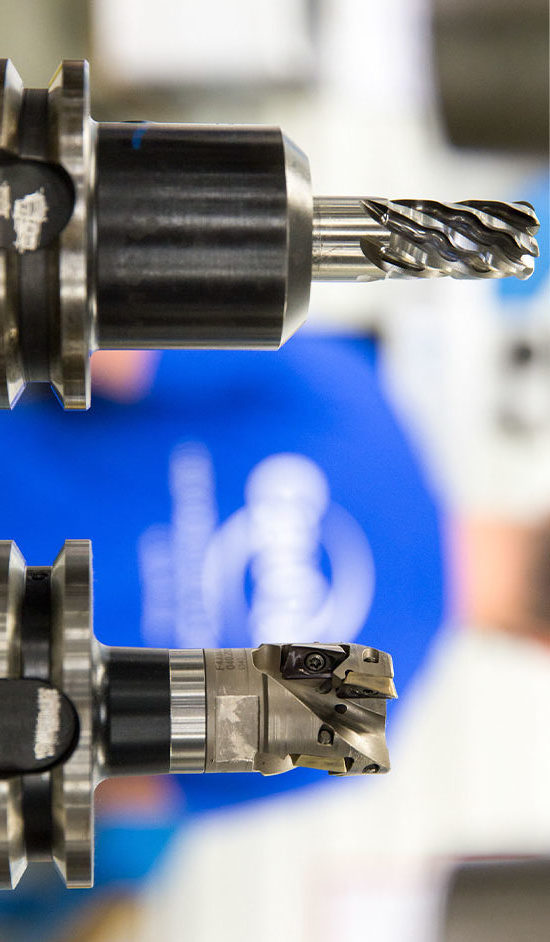

The techniques deployed at our sites include machining (small and large dimensions), sheet metal work, surface treatment, aerostructure assembly and the design and manufacture of metal and composite cabin equipment.

The Bt2i group is building a unique and innovative industrial model supported by :

- An experienced management team with strong expertise in complex high-tech operating environments.

- A real passion for managing multifaceted and sensitive activities.

- Solid experience of successful and excellent execution and innovation programs in fast-growing environments.

The Bt2i group is deployed via 2 centers of expertise and 8 sites specialized by technology, to offer a full range of capabilities.

ASD Division

- Small-scale machining, sheet metal work, boiler making, surface treatment and equipment in Bizerte, Tunisia.

- Management of complex mechanical projects in the defense and space sectors, through small and large-scale machining, and assembly in Eysines (33).

- Surface treatment, painting and non-destructive testing in Mérignac (33).

- Small-scale machining at Mondouzil (31).

- Complex boilermaking and structural assembly in Rochefort (17).

- Large-scale machining and mechanical assembly in Serres-Castet (64).

Cabin Division

- Production of composite components, trim and assembly at Bressols (82)

- Mechanical machining and assembly in Saintes (17).

The spirit of our Group is to propose a complete industrial offer covering :

- The product life cycle from design to repair.

- A wide range of technologies and materials that we can transform and assemble.

- Services ranging from series production to prototypes, tooling and the speed shop.

Our managerial approach is based on the support and ongoing training of our teams of experts within a context of profitability. We manage our resources in a way that promotes performance,agility, flexibility and synergies within the Group.

Our ambition is to become a global partner to our customers. To achieve this goal, we are constantly on the lookout for high-potential individuals willing to help us define and produce the next generation of high-tech products for the most innovative companies on the market.

Come and join our passionate teams and contribute to our success!

Executive Committee

1. Bizerte site

Business ParkFree Zone

7000 Bizerte

TUNISIA

2. Bressols site

ZI De Bressols50 impasse Fontanilles,

82710 Bressols

FRANCE

3. Eysines site

23 rue Saint-Excupéry,33320 Eysines

FRANCE

4. Head office - Mérignac site

9 Rue Bernard Palissy,33700 Mérignac

FRANCE

5. Mondouzil site

Chemin des Landes31850 Mondouzil

FRANCE

6. Rochefort site

Z.I. des Soeurs - Av. André Dulin17300 Rochefort s/Mer

FRANCE

7. Saintes site

ZI des Charriers,25 rue du Mouli de Paban,

17100 Saintes

FRANCE

8. Serres-Castet site

180 Place d'Ossau64121 Serres-Castet

FRANCE

The Bt2i group is committed to delivering complex services efficiently.

With this in mind, our companies began by controlling the quality of their products, then extended this control to all their key processes. Today, the Bt2i group has a Quality Management System based on the principle of continuous improvement. This approach is recognized by the EN 9100 and ISO 9001 certifications of all our companies.

" Our know-how, quality and respect for deadlines have become our greatest assets, and we are constantly striving to improve in order to best meet the needs of our principals, while keeping our finger on the pulse of the aeronautical world.